An Embedded micro controller – based precision instrument to help ensuring optimum operation of drying equipment. Ideal for precise Monitoring of moisture or Dew point analyzer used for compressed air or nitrogen gas output from dryers systems or in process. Continuous monitoring of dew point analyzer result in reduced maintains cost and downtime caused by separated moisture. The main cause of corrosion in pneumatic system. The dew point analyzer uses a highly accurate Capacities Integrated Thin Film Water vapour sensor and is an economic alternative to the chilled-mirror dew point analyzer type Meters. Dew Point Meter analyzer utilizes embedded micro control based circuits to give a direct – read out in dew point analyzer or other units and other units corresponding to sensor output based and Psychometric equations. To achieve high accuracy it uses temperature compensation over complete operational range..

SPECIAL FEATURES OF ONLINE DEW POINT ANALYZER :

Microprocessor based instrument.

Digital Graphical Display Measuring range ‐80° to +30° C dew

point & other ranges also available on client requirement.

Samples compressed air up to 12 Kg/cm.

Pressure and up to 95°C temperature can measure directly.

Quick disconnect fitting, desiccant test.

Handy and light weight.

Inbuilt thin film water vapor sensor.

Optional RS ‐ 485 computer interface & data logger.

ONLINE DEW POINT METER ANALYZER ADDITIONAL FEATURES:

Computer Interface: RS‐485 or USB

Data Logger: 1 Megabyte, Non‐Volatile Memory

In‐ built Pump: For Auto Suction

ONLINE DEW POINT ANALYZER SPECIFICATIONS :

Sensor Principle : Capacitive Thin Film PolymerDew Point Range : ‐ 80 TO +30°C

Relative Humidity : 0.001 to 99.999 %RH

Temp. : 0.01 to 99.99 ° C

Moisture : 0 to 23000 PPM

Accuracy : +/‐1°C for 0 to +30 °C

: +/‐1.5°C for 0 to ‐40 °C

: +/‐2 °C for ‐40 to ‐80 °C

Maximum Sample Temp : 90 °C (For higher temperature use, Optional cooling coil is available)

Maximum Pressure : 12kg/cm2

Response Time : 10 Seconds for 63% step change

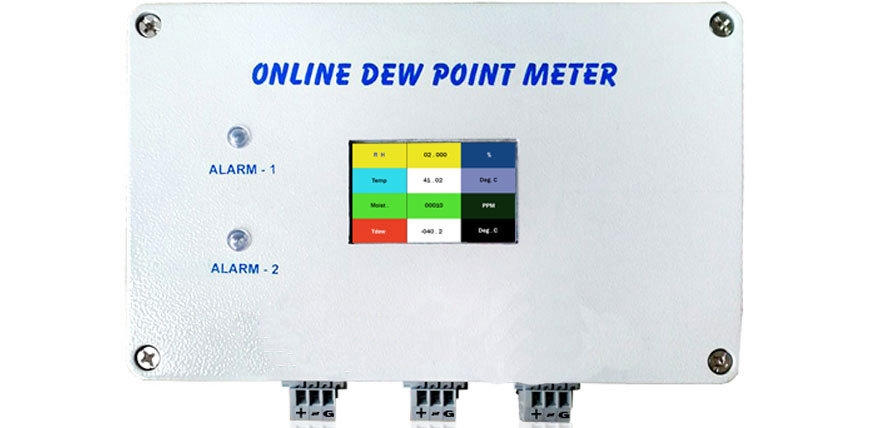

Display : 65K Colour Graphical Touch LCD

Power : Single cell lithium ion Battery with In‐built charge control

Inlet Sample Port : 1/4″ OD Tubing

Weight : 445 grams (approx.)

Dimensions : Refer to GA Drawing

Degree of Protection : IP ‐ 65

SAMPLING SYSTEMS:

Different sample conditioning systems are available, standard or bespoke, according to the process conditions. Filters, pumps and regulators can all be incorporated to deliver the sample in the correct condition.

Bypass flow systems enable longer distances from process to analyzer to be achieved. Tripurari Enterprises engineers are ready to recommend the right system for you on receipt of the full gas stream dew

point meter analyzer specification.

SAMPLING SYSTEM CONSISTS OF:

ISOLATING VALVE

Drain Valve

VACUUM PUMP

DUST FILTER

FLOW INDICATOR

SAMPLER COOLER